Maestro™ is a production data acquisition and exploitation software. It transforms production data into strategic advantage. It’s a purpose-built data software designed to optimize your composite manufacturing from AFP to RTM/SQRTM injection.

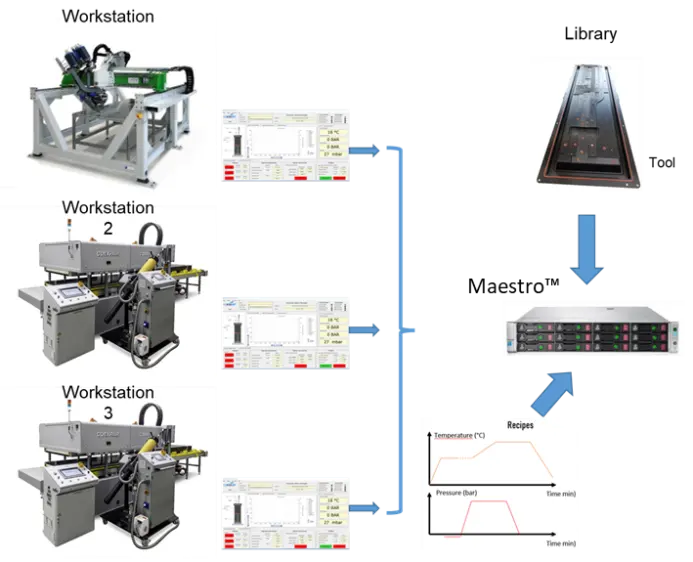

Maestro™ is specifically designed to aggregate composite manufacturing data from Coexpair presses, molds, and injection systems equipped with Floware™. This powerful tool centralizes all your production data in an SQL database, unlocking invaluable insights and driving continuous improvement.

Maestro™ includes a web-based unified dashboard providing a clear, real-time view of the entire production process. No more manual data collection, no more disparate systems. Maestro™ transforms data into actionable intelligence, empowering Materials and Process engineers, Quality Assurance and Maintenance teams to make informed decisions and optimize operations like never before.

Key Features:

- Comprehensive data acquisition: Captures a wide range of data points from injection systems, presses, vacuum and degassing stations, and more.

- Accessible anywhere: Maestro™ is a web-based interface accessible from any device.

- Real-time data: LIVE synchronization with production equipment ensures to have themost up-to-date information.

- Effortless statistics: Centralized data enables easy analysis of multi-workstation data, such as all injections performed with a specific mold across multiple presses.

- Automated traceability: Streamlines QA validation, automatic reporting, KPI generation, and communication with ERP systems.

Benefits of our System:

- Composite at its core: Maestro™ is specifically designed for AFP, RTM and SQRTM processes. All analyses, traceability features, and parameters are tailored to these processes, eliminating the need to configure a generic system.

- Increased efficiency: Eliminate wasted time spent on manual data collection and analysis. Automated reporting empowers Material & Process and Quality Engineers to concentrate on root cause analysis of defects and production improvements: higher-value activities.

- Cyber-safe: Maestro™ is installed on premise on a dedicated server safeguarding it from external threats.

- Simplified maintenance: Leverage statistical data for predictive maintenance, enabling better maintenance planning and reduced downtime.

- Tailored solution: As Coexpair develops its own software suite, Maestro™ can be customized to meet your specific requirements and seamlessly integrated systemslike ERP.