Coexpair designs and builds RTM and SQRTM Tools and handling devices. High Performance RTM process for aerospace is our job. The partnership with Radius Engineering ensures our Customers the same high quality & reliable equipment worldwide. Featuring high conductivity and high accuracy, our molds are key for successful composite part manufacturing.

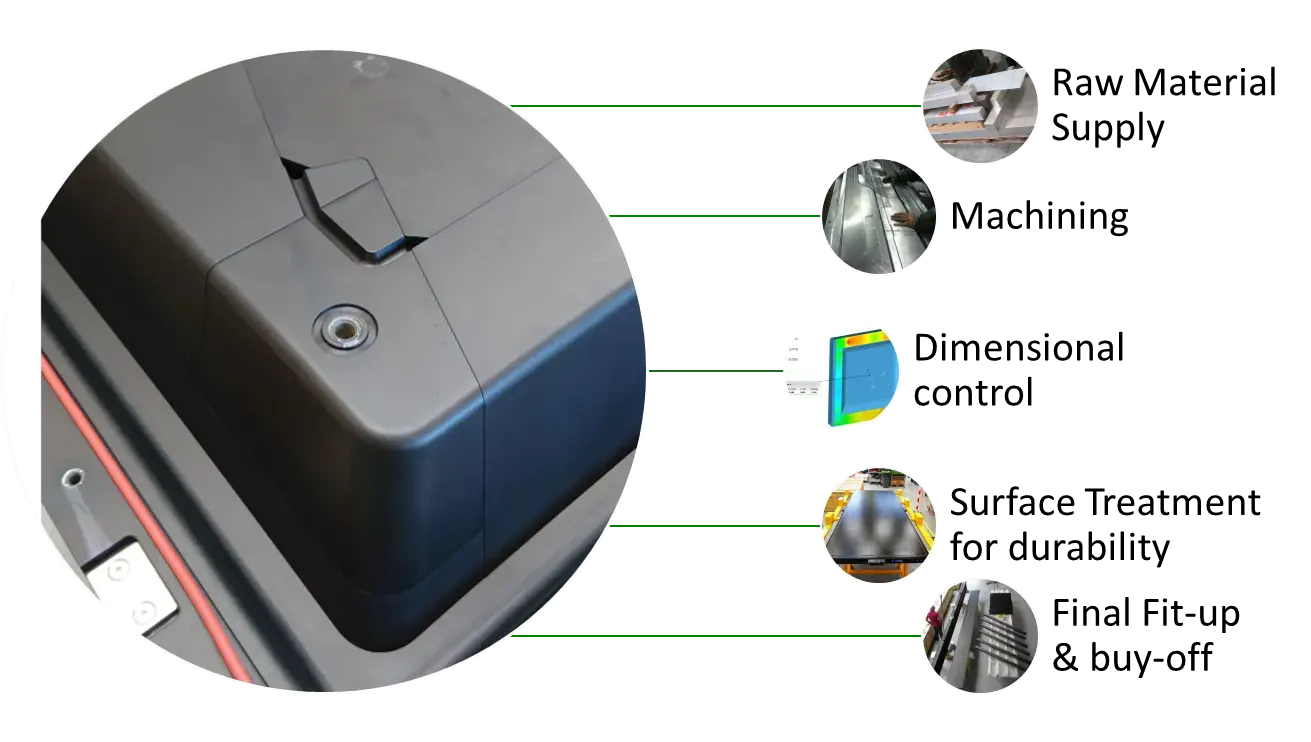

Coexpair fully industrial RTM & SQRTM mold features :

- High-quality design: With over 150 moulds delivered, we support our customers from concept development through to shopfloor integration

- Optimized for RTM or SQRTM process : FEM analysis for thermal behavior and deformation

- Accurate machining and fit-up to ensure cavity tolerance lower than +/- 0.15 mm

- Leak-rates < 1.33 mbar/min on 2 minutes with one seal

- Industrial solutions: easier cleaning, removable wear parts, repairs …

- Turnkey solutions: storage boxes, rotations systems, handling tools, preforming tools and demoulding, …

Benefits of Coexpair Molds in your composite shop :

- Short cycle time thanks to high conductivity material

- Increased production efficiency

- Reliability with Extremely Low Rate of Rejected Parts thanks to repeatable radii, high control of Fiber Volumic Fraction (Vf)

- Scalable supply-chain: from 0.5m to 12m, Coexpair has the right qualified machine-shop for your project.

.webp)

.webp)

.webp)

Got an RTM/SQRTM Project?

Let’s develop the tooling that meets your technical and industrial requirements together.