3-days (SQ)RTM training for Engineers & Technicians

Coexpair proposes a 3-days general introduction to RTM for Aerospace. It covers the process, the design, the materials and the equipment used. 2 parts are fabricated by the participants to illustrate the theory & provide hands-on learning (see hereunder). The program can be tuned following expertise and interest of attendants. The discovery of the SQRTM process by the manufacturing of one part, is proposed as an option.

Program

- 01- Introduction to aerospace composite processes. RTM & SQRTM state of the art.

- 02 – Illustrated presentation of the RTM and SQRTM processes.

- 03 - Practice in the shop: NC ply cutting and vacuum heat debulk. «Bulk factor » measurement. Mould preparation.

- 04 - Aerospace resin with their respective application (epoxy, BMI, etc…). Links between resin chemistry, mechanical properties and process.

- 05 - Aerospace reinforcement fibers (glass, aramide, carbon). Commercial denomination, architecture, mechanical performances & applications. Link between fiber surface & resin chemistry.

- 06 – Injection system. Presentation of different equipment (pressure controlled, flow controlled, pail un-loader, pressure pot). Pro & Cons. Risks and safety.

- 08 – Preforms for RTM: fabrics, braids, 3D. Usage and performances.

- 09 - Practice in the shop: First part: process understanding & spring-in effect illustration

- 10 - Lay-out of a typical RTM shop, from the stock of raw materials to the parts delivery.

- 11 - Practice in the shop: First part de-molding.

- 12 – Introduction to composite design & recommendations for RTM part design.

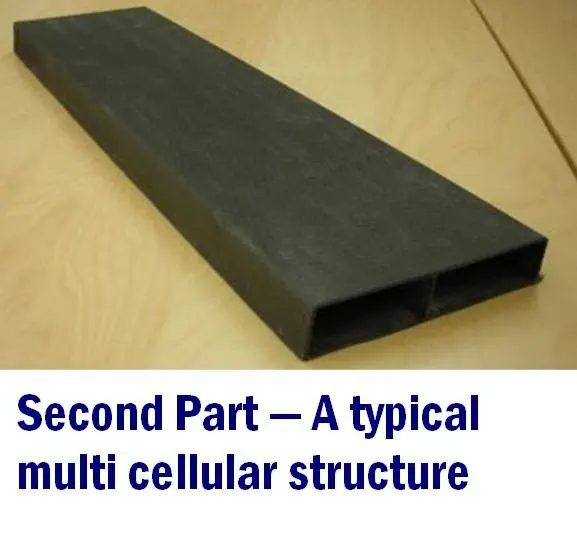

- 13 – Practice in the shop: Second part: a more complex preforming activity for a typical multi-cells part with removable mandrels

Location

This training is given at Coexpair in Belgium using Coexpair industrial equipment. Typical group size is 4-6 people.