The DiComEx project was selected under the Next Generation Combat Air Technologies (NGCAT) call, Theme 4: Transversal Disruptive Enabling Technologies. DiComEx unites Coexpair (coordinator), Sonaca, Pégard Productics, and the University of Liège, leveraging Belgium’s leadership in the SQRTM (Same Qualified Resin Transfer Molding) process - a key technology for advanced composite structures in next-generation combat aircraft.

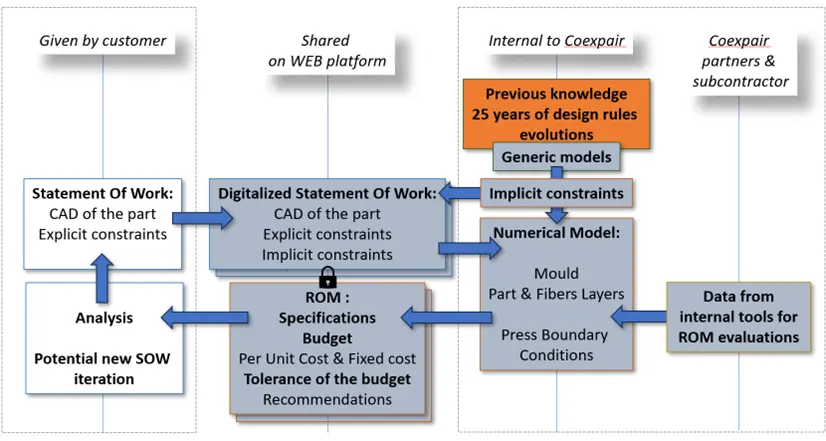

DiComEx’s goal is to develop a Belgian digital analytics system to consolidate and advance national expertise in composite manufacturing. The project will reduce development time and costs, minimize defect rates, and enhance production reliability, strengthening Belgium’s strategic autonomy in defence manufacturing. SQRTM enables the creation of monolithic composite parts, replacing multiple components and assembly steps, but demands high expertise and robust digital tools to mitigate the risk of costly defects.

Currently, developing complex SQRTM parts is slow and fragmented. DiComEx addresses this by integrating all analytics and workflows into a unified digital toolkit, surpassing the limitations of existing commercial systems. This responds to growing interest from major aerospace players in Coexpair’s digital solutions.

DiComEx will directly boost the competitiveness and autonomy of Belgium’s defence industry, enabling faster, more reliable composite part development and supporting advanced materials, digital twins, and energy-efficient processes. It is a cornerstone for Belgium’s defence innovation, embedding data-driven composite manufacturing as a national strength.

Project

DiComEx – Digital Composite Expertise

Project overview

3 partners – €994.000 budget

Program

Project funded by the Belgian

Royal Higher Institute for Defense (RHID)

Project Website

(ongoing)